MEKTEC Corporation: Leading the Way in FPC Manufacturing through In-House Development of Materials and Equipment (Part 2)

Mektec Corporation is a member of the NOK Group based in Minato City, Tokyo, and led by President Taro Ito. Flexible printed circuits (FPC) manufactured and sold by Mektec continue to evolve in line with the diversification of electronic devices. As these products advance toward ever-greater thinness and multilayer structures, they are also expected to deliver higher functionality and durability than ever before. One notable trend in recent years has been the emergence of foldable smartphones, which have attracted significant attention, particularly among Chinese and Korean manufacturers. In these devices, the hinge section connecting the two display panels requires an ultra-flexible FPC capable of withstanding several hundred thousand bending cycles. Meanwhile, with the progress of 5G and other high-speed, high-capacity communications technologies, demand has grown for FPC that can reliably transmit high-frequency signals. Mektec continues to meet these evolving needs with its proven technological expertise and integrated development capabilities.

Materials and structures that can withstand millions of bends

FPC have long been central to the evolution of mobile communication devices, tracing their history back to the era of feature phones. Today’s foldable smartphones combine the portability of a phone with the expansive usability of a tablet, allowing multitasking across dual screens — an innovation expected to fuel further market growth.

According to Katsushi Meguro of the Global Engineering Department, Engineering Division, who has been involved in FPC development and manufacturing for many years, “Mektec’s ultra-flexible FPC hold more than 50% of the market share in China’s foldable smartphone segment. They have earned a strong reputation for never breaking, even after millions of bends.”

So what enables Mektec’s FPC to achieve such exceptional durability? Yasuyuki Ito, Manager of the New Material Development Section, R&D Department, Engineering Division, explains: “Our strength lies in our extensive development track record and accumulated data, which allow us to identify the ideal combination of films, copper foils, and adhesives to achieve outstanding flex resistance.”

A key contributor to this performance is Mektec’s in-house-developed adhesives, which play a decisive role in improving FPC flexibility. Unlike many manufacturers, Mektec develops not only its circuit designs but also the core materials that make them possible, including adhesives. They draw on years of expertise to fine-tune their physical properties for optimal performance.

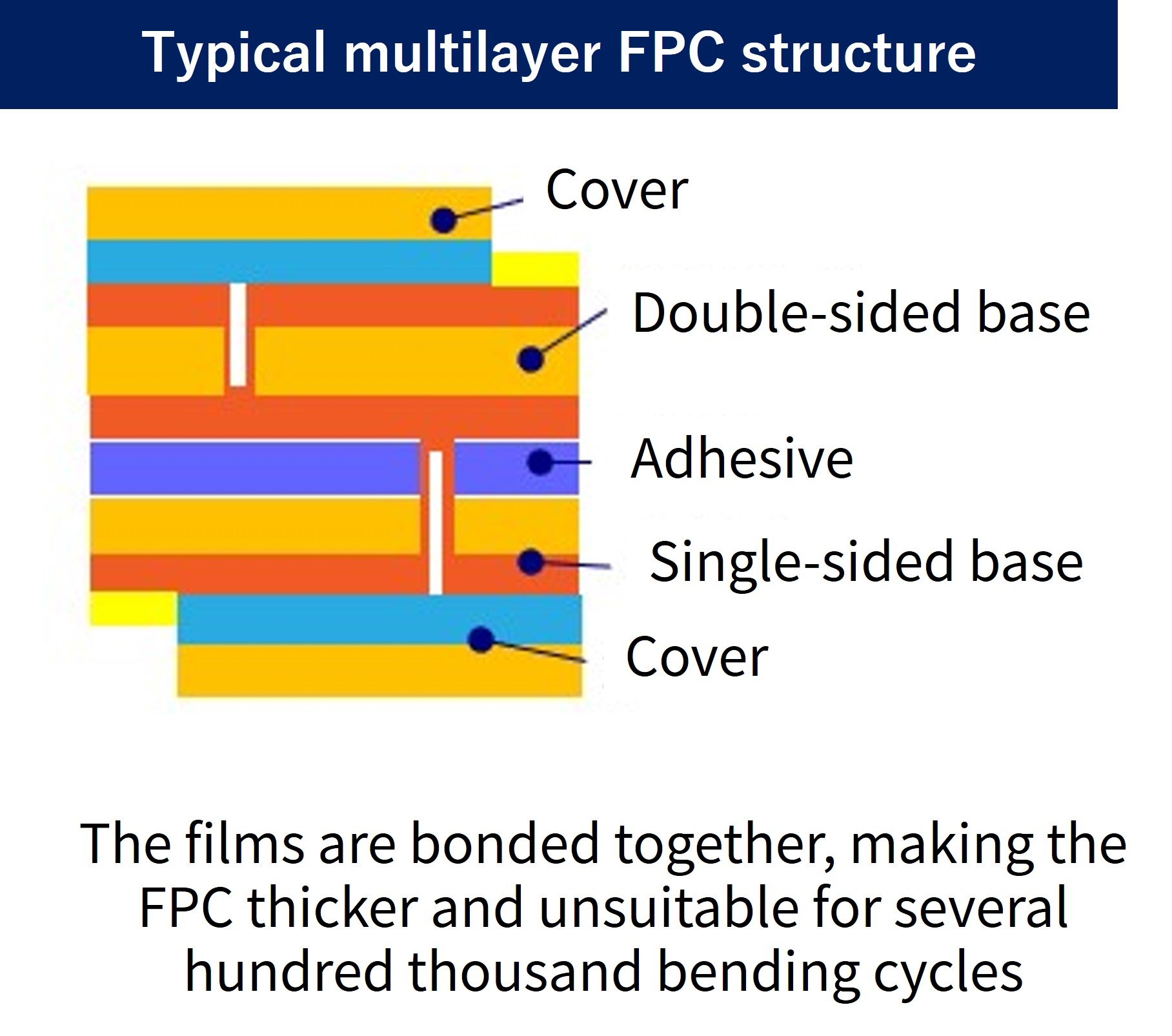

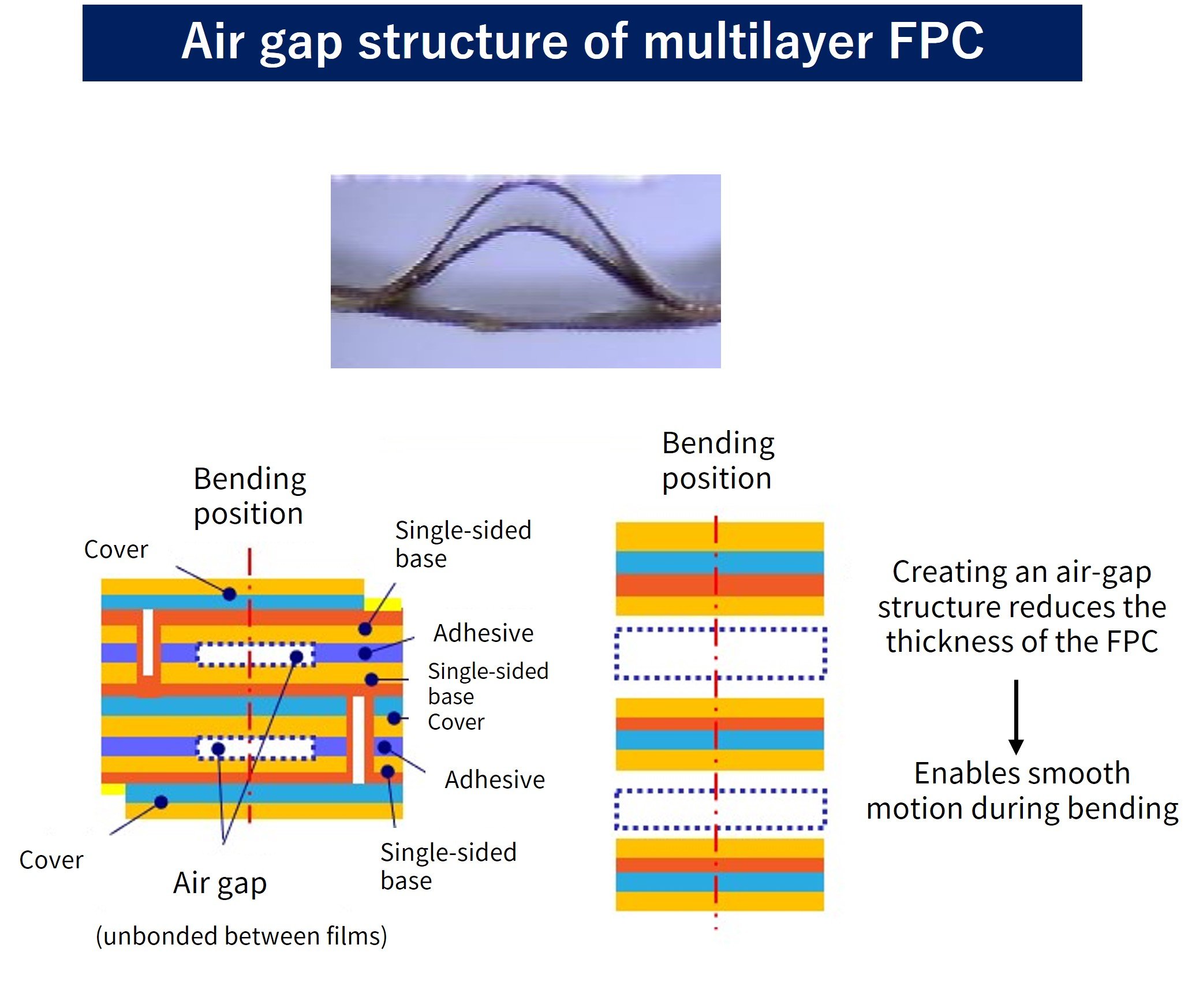

Another cornerstone of Mektec’s technological leadership is its proprietary method for producing FPC with a hollow structure, in which selected layers are intentionally left unbonded. By thinning only the folding area, this design enables smooth and natural motion. However, because the inner and outer surfaces of the fold experience different stress levels, precise control of layer thickness and positioning is essential. To optimize these structures, Mektec combines its extensive historical data with advanced simulation technology to analyze stress distribution in fine detail. This data-driven approach allows the company to determine the most effective structural configurations to deliver the required level of durability and flex resistance.

Masahiro Mineki, Supervisor of Engineering Central Operation, Global Engineering Management, Engineering Division, explains, “The key to enhancing the flexibility of FPC lies in how effectively we can suppress the formation of microscopic cracks in the copper foil layers. Based on precise measurement data, we select the optimal materials and design the structure accordingly. We also have an environment where we can verify the material combinations through simulation, ensuring highly reliable FPC.” Thanks to Mektec’s diverse technologies, the company has developed FPC optimized for hinges that require exceptional flexibility, earning them a commanding share of the market.

Minimizing signal loss through material, structural, and design optimization

As data transmission demands grow with high-definition video and real-time communication, radio frequencies used for communication have become increasingly higher with each generation. High frequency means more wave cycles per second, allowing larger amounts of data to be transmitted in shorter time spans. Current fifth-generation (5G) networks use frequencies of 3.7 GHz and 4.5 GHz, as well as millimeter waves ranging from 24.25 to 71 GHz. The next generation, 6G, is expected to operate in the sub-terahertz range, between 90 and 300 GHz.

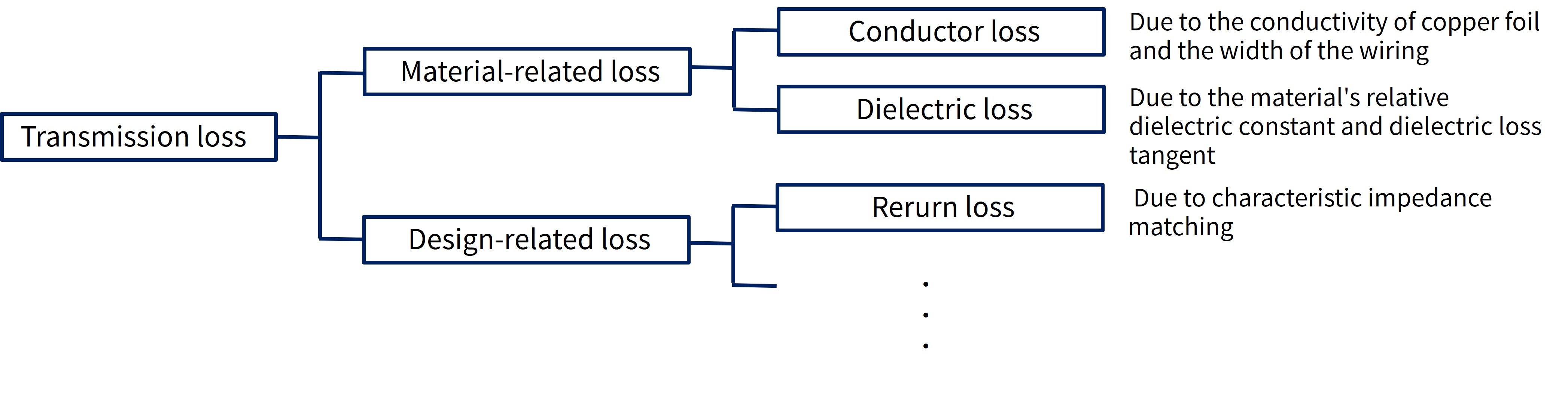

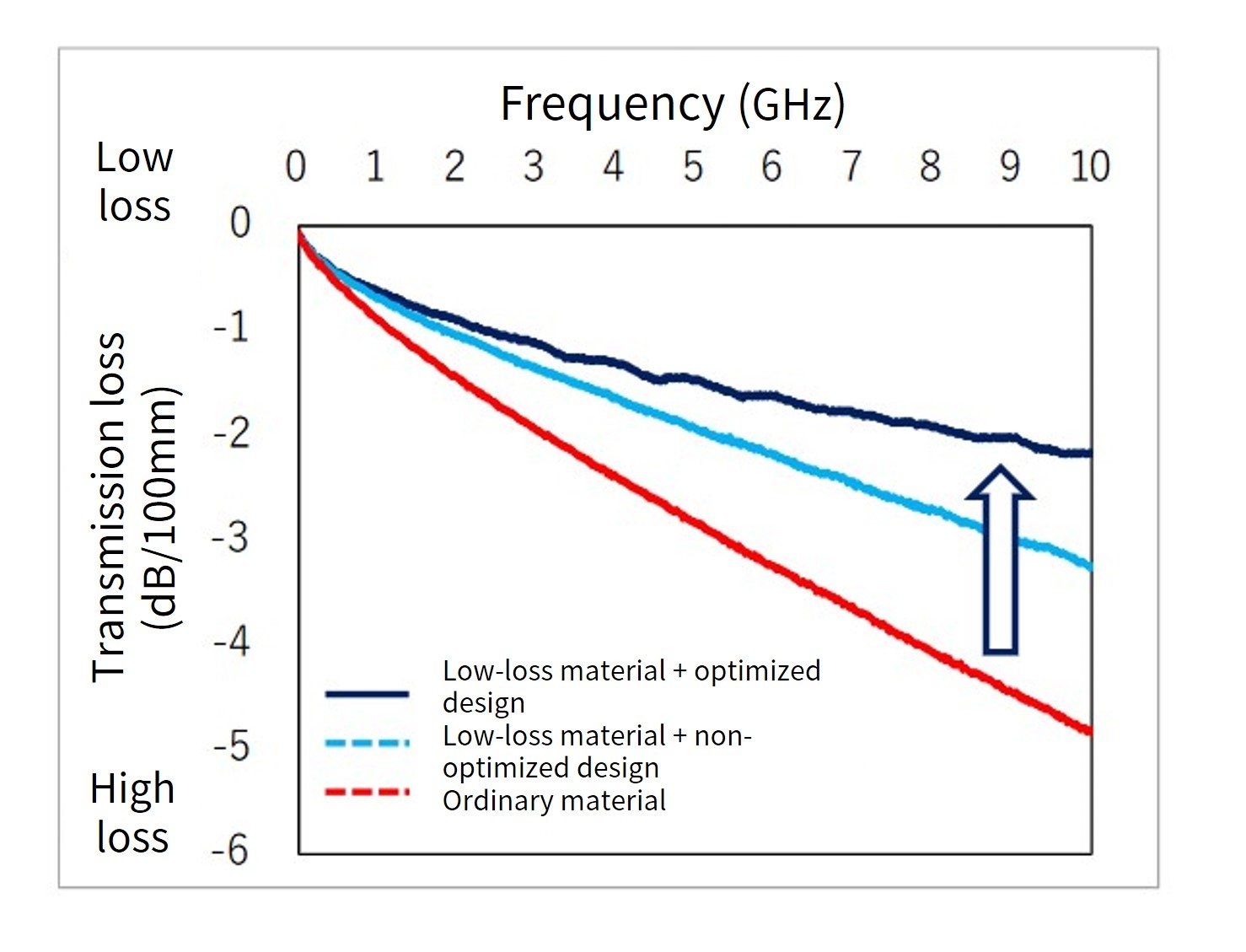

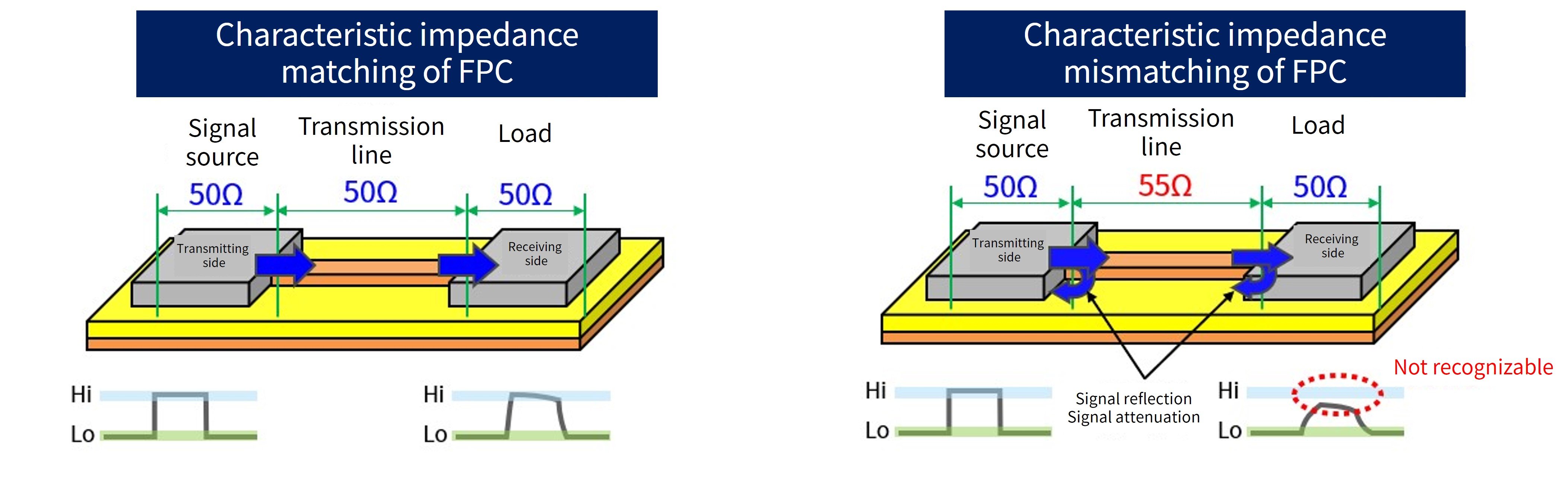

Naturally, the FPC used in communication devices must also be capable of handling high frequencies. “To transmit signals accurately, it’s essential to minimize signal attenuation, or transmission loss,” says Mineki. “That means selecting materials that resist energy loss as heat at high frequencies, and designing the circuit so that the characteristic impedance — the resistance between the transmitting and receiving connectors—remains consistent.” Even if the materials are ideal, deviations in characteristic impedance from the target value can cause signal reflections and losses, preventing accurate transmission. “The higher the frequency, the more significant the impact of impedance mismatch on signal attenuation,” adds Manager Yasuyuki Ito. Achieving impedance matching is therefore a critical challenge unique to high-frequency design.

According to Mineki, factors such as the physical properties of materials, the thickness of the FPC, and the distance between circuit layers all have a strong influence on impedance matching. In foldable smartphones, where both high flexibility and high-frequency performance are required, Mektec uses hollow structures. However, because the films in a hollow structure are not bonded, the layer-to-layer distance varies depending on the bending position, which can destabilize the impedance. Adjusting circuit widths and designing the overall structure with the hollow configuration in mind are therefore essential.

Through repeated simulation and accumulated technical expertise, Mektec has developed the capability to identify the optimal structural design for impedance matching — one of its key strengths. During production, the company maintains rigorous process control, precisely managing layer-to-layer alignment and performing comprehensive continuity testing on every unit. Looking ahead, Mektec is actively developing products to meet the demands of next-generation 6G communications, which will operate at even higher frequencies.

Creating new value through evolving proprietary technologies

Mektec has long led the FPC industry with its proprietary material formulations, manufacturing technologies, and advanced simulation-based analysis. Expanding beyond its traditional strength in mass production, the company now also focuses on multi-variety, small-lot manufacturing that offers customized performance tailored to user needs. With electronics becoming ever more integral to fields such as autonomous driving and human-collaborative robotics, Mektec continues to anticipate new sources of value. By enhancing its manufacturing efficiency, expanding its roll-to-roll processes, and strengthening quality management and design, the company remains steadfast in its mission to deliver innovative and socially valuable solutions for the future.

(Left)

Yasuyuki Ito

Manager, New Material Development Section, R&D Department, Engineering Division

After joining MEKTEC (formerly Nippon Mektron), Ito has been engaged in material engineering. His work covers the full spectrum of material-related operations, from evaluation and introduction of new materials to improvement of existing ones and reliability testing of FPC.

(Center)

Masahiro Mineki

Supervisor, Engineering Central Operation, Global Engineering Management, Engineering Division

Since joining MEKTEC (formerly Nippon Mektron) in 2014, Mineki has been involved in FPC design and process engineering. From 2020, he was stationed for five years at the Zhuhai Plant in China, where he worked on developing and designing FPC for electronic devices, including foldable smartphones. He currently oversees global technology coordination and promotion within Engineering Central Operation.

(Right)

Katsushi Meguro

Global Engineering Management, Engineering Division

Meguro joined MEKTEC (formerly Nippon Mektron) in 1988 and has been engaged in FPC manufacturing technology. From 2014, he was assigned to the Thailand Plant for eight years, where he was responsible for technical improvement and coordination with Japan. After returning to Japan in 2022, he now serves as a senior staff member, applying his extensive experience in his current role.