MEKTEC Corporation: Leading the Way in FPC Manufacturing through In-House Development of Materials and Equipment (Part 1)

Mektec Corporation, based in Minato City, Tokyo, and led by its President, Taro Ito, is an electronic components manufacturer engaged in the production and sales of flexible printed circuits (FPC). Established in 1969, the company operates its main plant at Ushiku, Ibaraki Prefecture, with manufacturing sites in China, Southeast Asia, Taiwan, and Europe, and sales offices across Asia, Europe, and the Americas. By conducting product development in multiple regions, Mektec has built a global supply network capable of meeting the needs of local markets.

Leveraging NOK Group’s advanced material compounding technologies, Mektec develops its own adhesive and related materials, achieving one of the world’s leading market shares in the FPC industry. In addition to its astounding production capacity, the company also manufactures products with high added value that can be used in smartphones and automobiles, where thinner, lighter, and more functional components are in demand.

This feature on Mektec will be presented in two parts. The first part focuses on the technological capabilities that support its exceptional production volume, while the second explores the technologies behind Mektec’s value-added products that are being developed in response to evolving market needs.

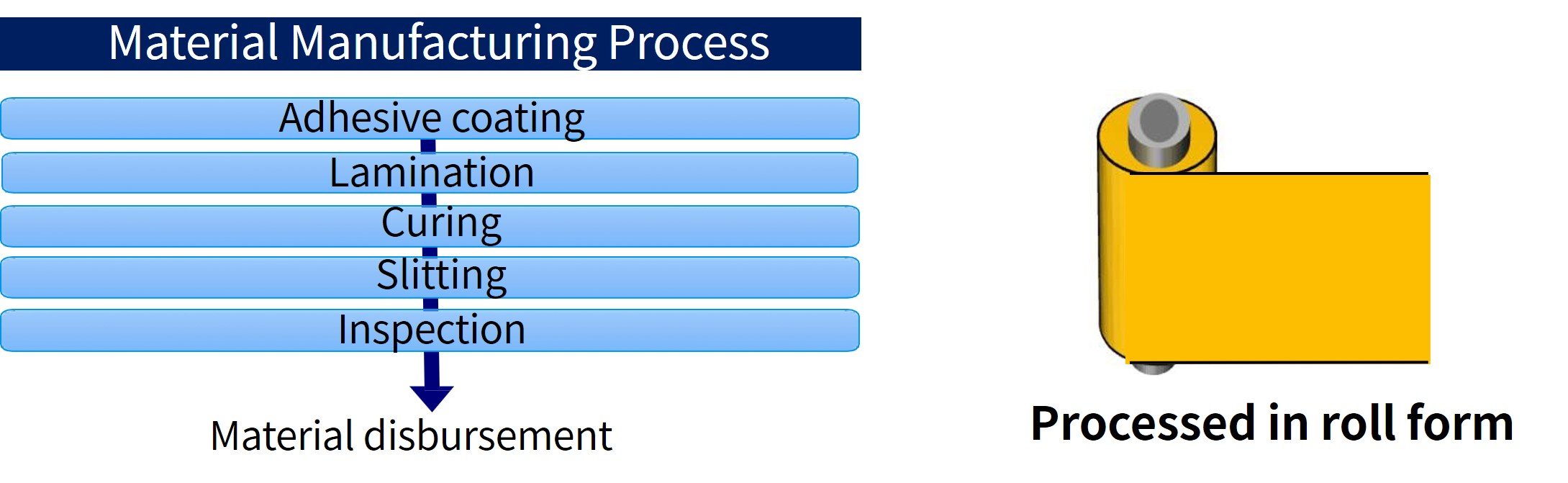

FPC Manufacturing Process

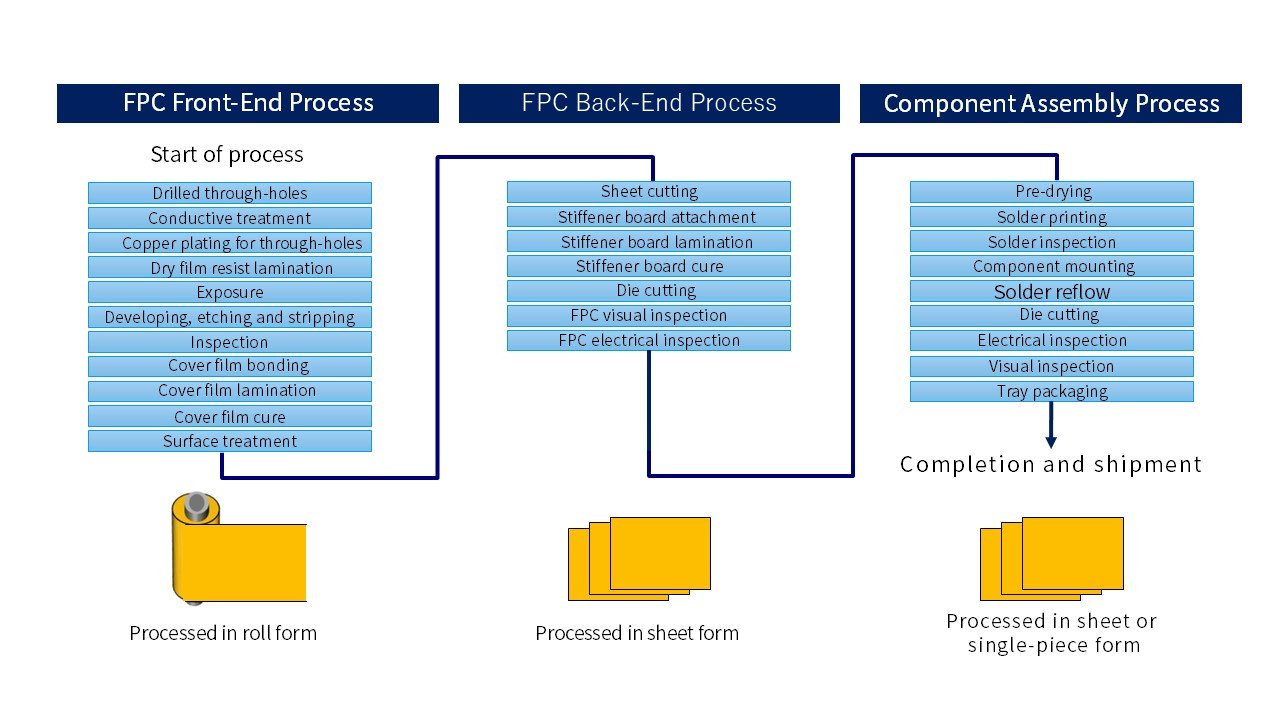

FPC primarily consist of three components: an insulating film (polyimide), copper foil, and adhesive. The key feature lies in their thin, lightweight, and highly flexible structure. Thanks to these characteristics, FPC offer greater freedom in design and circuit layout, accelerating the shift from conventional rigid boards and wire harnesses to flexible printed circuits. The manufacturing process of FPC is divided into front-end processes, including circuit and insulation layer formation, and back-end processes, from shape processing to final inspection before shipment. Each step requires sophisticated technology and precise control.

At Mektec, FPC manufacturing begins with the creation of a “rolled material” formed by laminating copper foil onto an insulating film (polyimide).

For double-sided FPC, through-holes that vary in diameter from less than 0.1 millimeter to several millimeters are formed in the rolled material to create layer-to-layer connections. A conductive treatment is then applied, forming a conductive treatment along the inner walls of these holes, which are otherwise non-conductive. Next, the entire material, now uniformly conductive, is immersed in a plating solution, where an electric current is applied to deposit* a copper plating layer.

Following this, a dry film (a photosensitive material in film form) is laminated and exposed to light to define the circuit pattern. Using a method called the DES process, only the copper foil corresponding to the circuit design is retained. A polyimide cover film is then laminated onto the surface, and heat-resistant, anti-corrosion, or gold-plating treatments are applied to the exposed openings in the cover film. These steps constitute the front-end process of FPC manufacturing.

Deposition: A phenomenon in which a substance in a non-solid state forms a solid layer.

In the back-end process, the rolled material is first cut into sheets. Reinforcing materials are then laminated and cured, after which the material is die-cut into the final product shape. Electrical and visual inspections are conducted to ensure circuit quality and reliability, followed by the mounting of components required for each specific product. Through this series of intricate and highly controlled processes, FPC are completed.

Establishing the Roll-to-Roll Method for High-Volume Production

According to Yasuyuki Ito, Manager of the New Material Development Section, R&D Department, Engineering Division, one of the key factors behind Mektec’s world-leading market share is their “in-house development of materials and manufacturing equipment, supported by the Roll-to-Roll production method.” In the past, FPC were processed one sheet at a time. However, because FPC materials are thin and flexible, manual handling often led to wrinkles and other defects, resulting in variations in quality both within and between sheets.

To address this, Mektec established its proprietary Roll-to-Roll production method in 2004. Originally used in film material production, this technique involves feeding rolled film through manufacturing equipment and rewinding it on the opposite side. By adapting this method for FPC manufacturing and developing original production machinery in-house, Mektec succeeded in creating a new, more efficient manufacturing process. This innovation not only reduced defects such as wrinkling but also enabled high-volume production with consistent quality, dramatically improving manufacturing efficiency.

Achieving Greater Precision through Original Materials and Quality Standards

When producing FPC in sheet form, another challenge arose: the material could stretch when boring holes or under tension, causing unevenness. To maintain uniformity before drilling, Mektec collaborated with material manufacturers to develop new wrinkle-resistant materials and optimized material composition and structure to ensure stability under processing tension.

In 2014, the company also introduced its own proprietary quality standards to further strengthen quality control. Because through-hole quality directly affects the reliability of the final product, Mektec developed methods to apply optimal tension while minimizing debris from drilling. To meet customer demand for increasingly miniaturized products, the company also developed manufacturing equipment capable of CO₂ laser processing, allowing for finer and more precise drilling.

Manufacturing Technologies That Pioneer the Future

As a result of these advances, Mektec can now perform all front-end processes — from through-hole formation to surface treatment (such as gold plating) — continuously in roll form. According to Katsushi Meguro of Global Engineering Management, Engineering Division, “The establishment of the Roll-to-Roll method has enabled stable quality, labor savings through automation, and further miniaturization of products, laying the foundation for Mektec’s current manufacturing capabilities.”

Masahiro Mineki, Supervisor of Engineering Central Operation, Global Engineering Management, Engineering Division, adds, “Mektec has continuously evolved its production technologies in step with the advancement of electronics. Today, we are focusing not only on mass production of single models but also on developing production technologies for high-mix, low-volume manufacturing to meet increasingly diverse market needs.” Going forward, Mektec aims to expand the Roll-to-Roll method to encompass all processes, including the back-end stages of production.

(Left)

Yasuyuki Ito

Manager, New Material Development Section, R&D Department, Engineering Division

After joining MEKTEC (formerly Nippon Mektron), Ito has been engaged in material engineering. His work covers the full spectrum of material-related operations, from evaluation and introduction of new materials to improvement of existing ones and reliability testing of FPC.

(Center)

Masahiro Mineki

Supervisor, Engineering Central Operation, Global Engineering Management, Engineering Division

Since joining MEKTEC (formerly Nippon Mektron) in 2014, Mineki has been involved in FPC design and process engineering. From 2020, he was stationed for five years at the Zhuhai Plant in China, where he worked on developing and designing FPC for electronic devices, including foldable smartphones. He currently oversees global technology coordination and promotion within Engineering Central Operation.

(Right)

Katsushi Meguro

Global Engineering Management, Engineering Division

Meguro joined MEKTEC (formerly Nippon Mektron) in 1988 and has been engaged in FPC manufacturing technology. From 2014, he was assigned to the Thailand Plant for eight years, where he was responsible for technical improvement and coordination with Japan. After returning to Japan in 2022, he now serves as a senior staff member, applying his extensive experience in his current role.