Differentiation Through In-House Adhesive Development

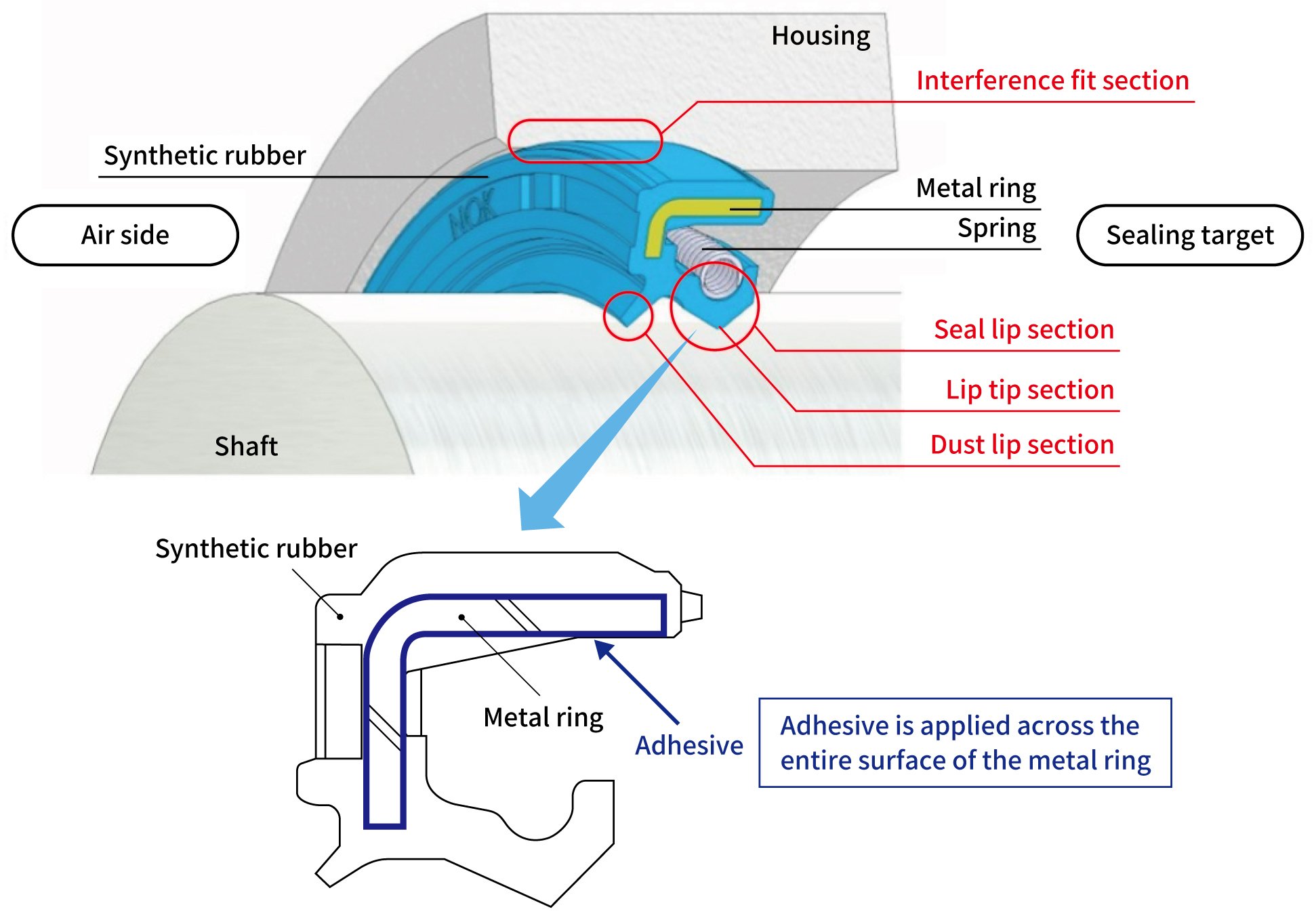

One of NOK’s signature products, the oil seal, is typically made by combining rubber, a metal ring, and a spring. Adhesives are used to integrate these different materials into a single unit. However, bonding dissimilar materials such as rubber and metal is technically challenging, and oil seals must also perform reliably in demanding environments. For instance, they need to maintain adhesion while exhibiting heat and oil resistance, even at temperatures exceeding 100°C. To meet these stringent specifications, NOK has developed its own in-house adhesives for over 60 years.

Meeting complex demands

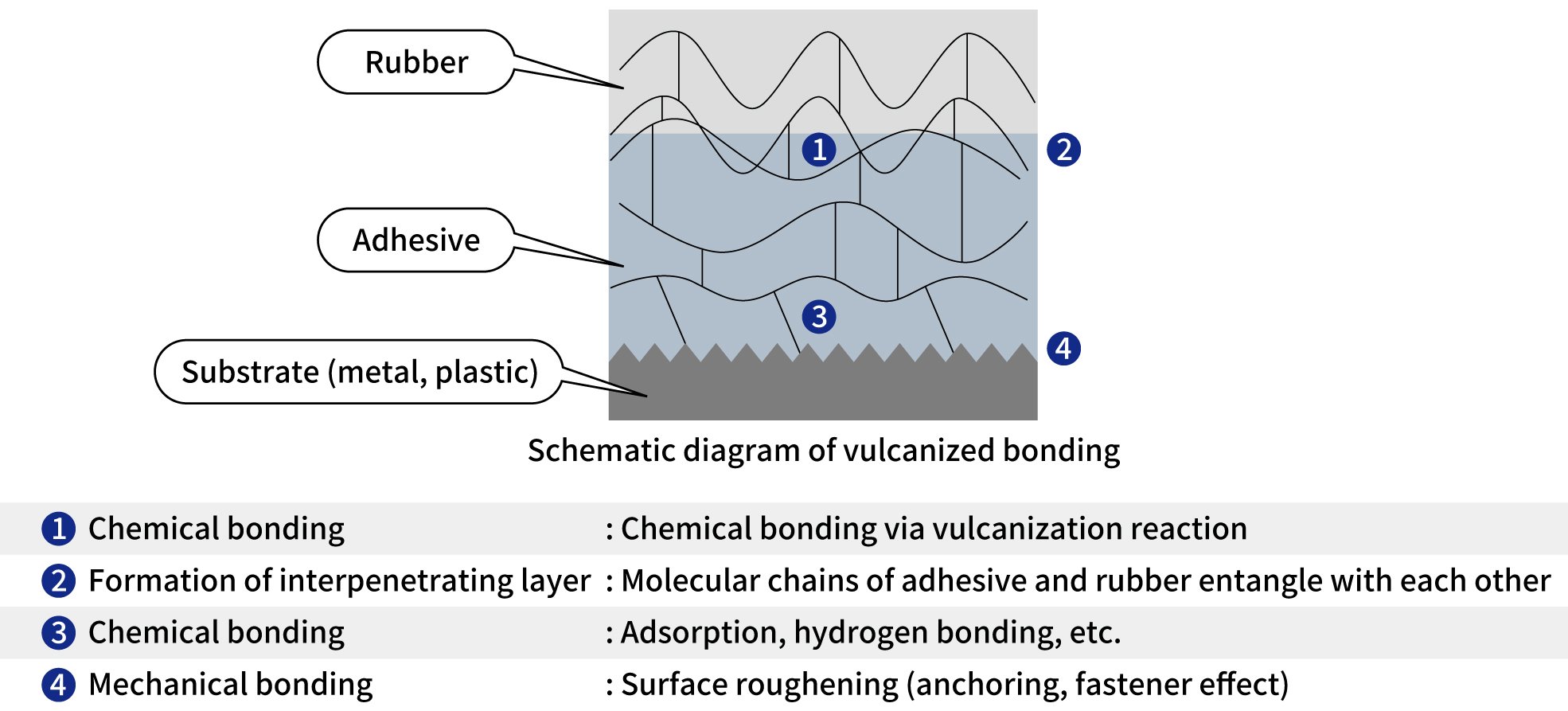

Adhesives are critical in securely bonding two target materials, known as adherends. The type of adhesive and bonding method varies depending on the materials involved. There are three primary bonding mechanisms. One is mechanical bonding, in which the adhesive flows into microscopic surface irregularities, commonly used with wood and paper, then hardens to form a connection. Another is chemical bonding, where atoms in the adhesive and adherend share electrons to form strong links. The third is physical bonding, where molecules are drawn together by intermolecular forces.

The bonding process used to adhere rubber and metal in oil seal production is known as vulcanized bonding, which combines all three bonding mechanisms. During vulcanization molding, physical bonding through intermolecular forces and chemical bonding via chemical reactions occur simultaneously at the bonding interface. Achieving this requires extremely precise control over factors such as the type of adhesive, surface treatment conditions, and vulcanization parameters (temperature, time, pressure, etc.).

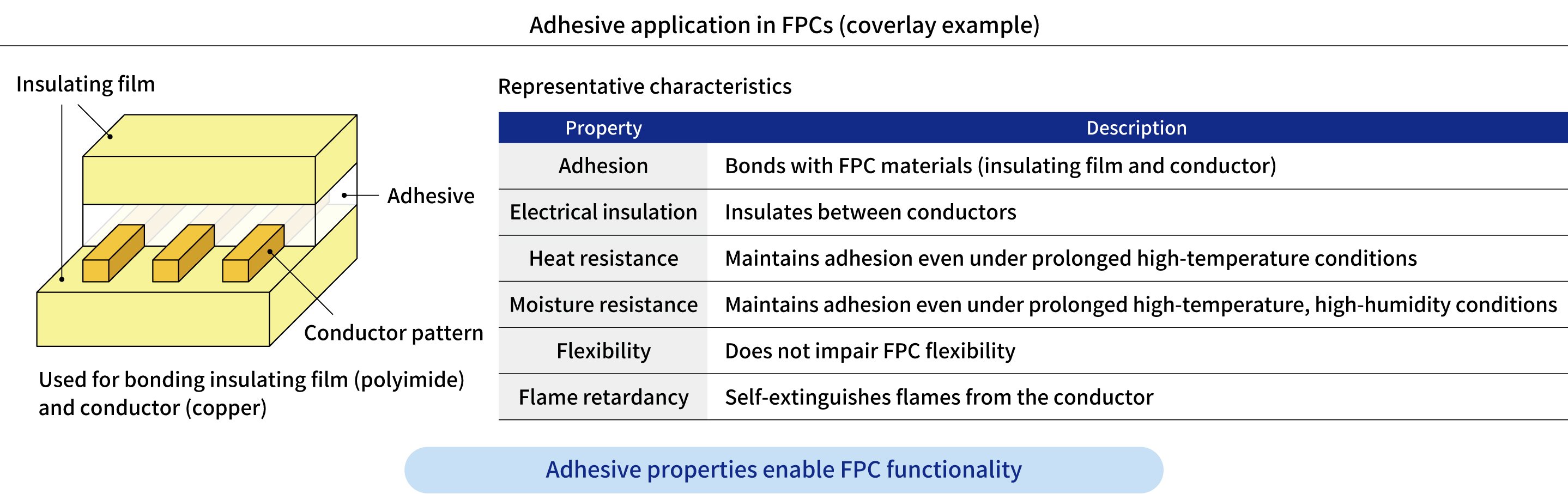

The flexible printed circuits (FPC) manufactured by Mektec, a member of the NOK Group based in Tokyo, leverage NOK's extensive expertise in adhesive development built over many years. FPC are printed circuit boards formed with circuit patterns on thin, flexible plastic film substrates. Because they can be repeatedly bent and folded, they are widely used in smartphones and computers and in a range of other electronic devices and contribute to device miniaturization. FPC are produced by bonding copper foil to a film using adhesive, forming electronic circuits, and then laminating a cover film on top. Adhesive is used in this process, and the adhesive itself must possess insulating properties. In addition, it must offer heat resistance, moisture resistance, flexibility, and flame retardancy. These requirements highlight the essential role adhesives play in enabling the functionality of FPC.

Achieving high performance through in-house

The Materials Development Department at the Shonan R&D Center in Fujisawa, Kanagawa Prefecture, leads NOK Group's adhesive development. This department oversees adhesive development for the entire Group, including Mektec. According to Isao Yoshitake, Manager of the Seal Products Adhesive Development Section, around 150 types of adhesives are currently developed in-house for seal products and about 15 types for FPC. "It's quite rare for an industrial manufacturer like NOK to produce its own adhesives," he notes. By developing adhesives tailored to each product, NOK can meet demanding performance requirements; this accumulation of technical expertise underpins the development capabilities of the NOK Group.

New adhesives are developed when entirely new properties are needed. Wataru Kojima, Manager of the High-Performance Adhesive Development Section, which handles adhesives for newer fields such as FPC, says, "Lately, our mission has also expanded to pioneering new fields by developing adhesives that leverage NOK's unique strengths."

Expanding into new fields by leveraging heat resistance

Yoshitake describes adhesive development as “a behind-the-scenes force that also plays a highly visible role in determining product performance.” Adhesive development is closely tied to product development from the earliest stages.

As industries evolve rapidly, new demands for adhesives continue to emerge. In the automotive industry, the growing adoption of electric vehicles (EVs) is driving such changes. Kojima explains, “Where oil resistance was once essential for engine applications, we’re now seeing a shift toward properties like alkali resistance.”

In recent years, NOK has not only focused on internal development for the NOK Group but has also actively expanded sales to other companies. While responding to new requirements is vital, the adhesive market is crowded with competitors. NOK believes its unique differentiator lies in adhesives that combine heat resistance and strong adhesion, and it plans to focus its proposals on applications where heat resistance is critical.

Reducing environmental impact is another important area of focus. Development is moving toward adhesives that minimize the use of organic solvents and that do not require heat during bonding. Efforts are also underway to improve development efficiency, such as by building databases to reduce the number of prototypes and experiments. NOK is also collaborating with universities and research institutions to establish a broader technological foundation.

(Photo: left)

Isao Yoshitake

Manager, Seal Products Adhesive Development Section, Materials Development Department, NOK Group R&D, NOK Corporation

After joining NOK in 2008, Yoshitake was assigned to his current department, where he worked on developing adhesives and coating agents. In 2015, as part of a job rotation program, he transferred to the Oil Seal Division, where he spent a year engaged in manufacturing technology operations. He returned to his original department in 2016 and has led development efforts as section manager since 2023.

(Photo: right)

Wataru Kojima

Manager, High-Performance Adhesive Development Section, Materials Development Department, NOK Group R&D, NOK Corporation

After joining NOK in 2002, Kojima was assigned to Nippon Mektron (now Mektec), where he worked on introducing and developing FPC materials. In 2020, he transferred to Unimatec, where he was involved in the development of FPC adhesives. He moved to NOK in 2024 and currently leads the development of both FPC adhesives and commercial adhesives as section manager.

All data, titles, and affiliations in this article are as of April 2025.