End-to-End Development of Precision Plastic Products: ESTOH (Part 2)

Approximately 90% of ESTOH Co., Ltd.'s (Headquarters: Ikuno-ku, Osaka, President: Kenji Nakamura) products are plastic gaskets for automotive lithium-ion batteries (LiBs). One of the company's key goals is to expand its market share in this field by leveraging NOK's marketing strengths to stay aligned with ever-evolving customer needs. At the same time, ESTOH is focused on expanding into new sectors by making full use of its vertically integrated production capabilities for precision plastic components.

ESTOH’s manufacturing foundation

Three core departments underpin ESTOH’s strengths: mold engineering, injection molding, and quality assurance. The sales department supports these and works to identify customer needs and provide direct feedback on product challenges to the technical teams.

Please enlarge the screen to view

The injection molding department has automated processes such as material supply and product ejection, enabling round-the-clock production in three shifts. Automation also includes image-based inspection systems, ensuring every molded part is checked immediately after molding and again during post-processing. This dual-layer inspection approach minimizes the occurrence of defective products.

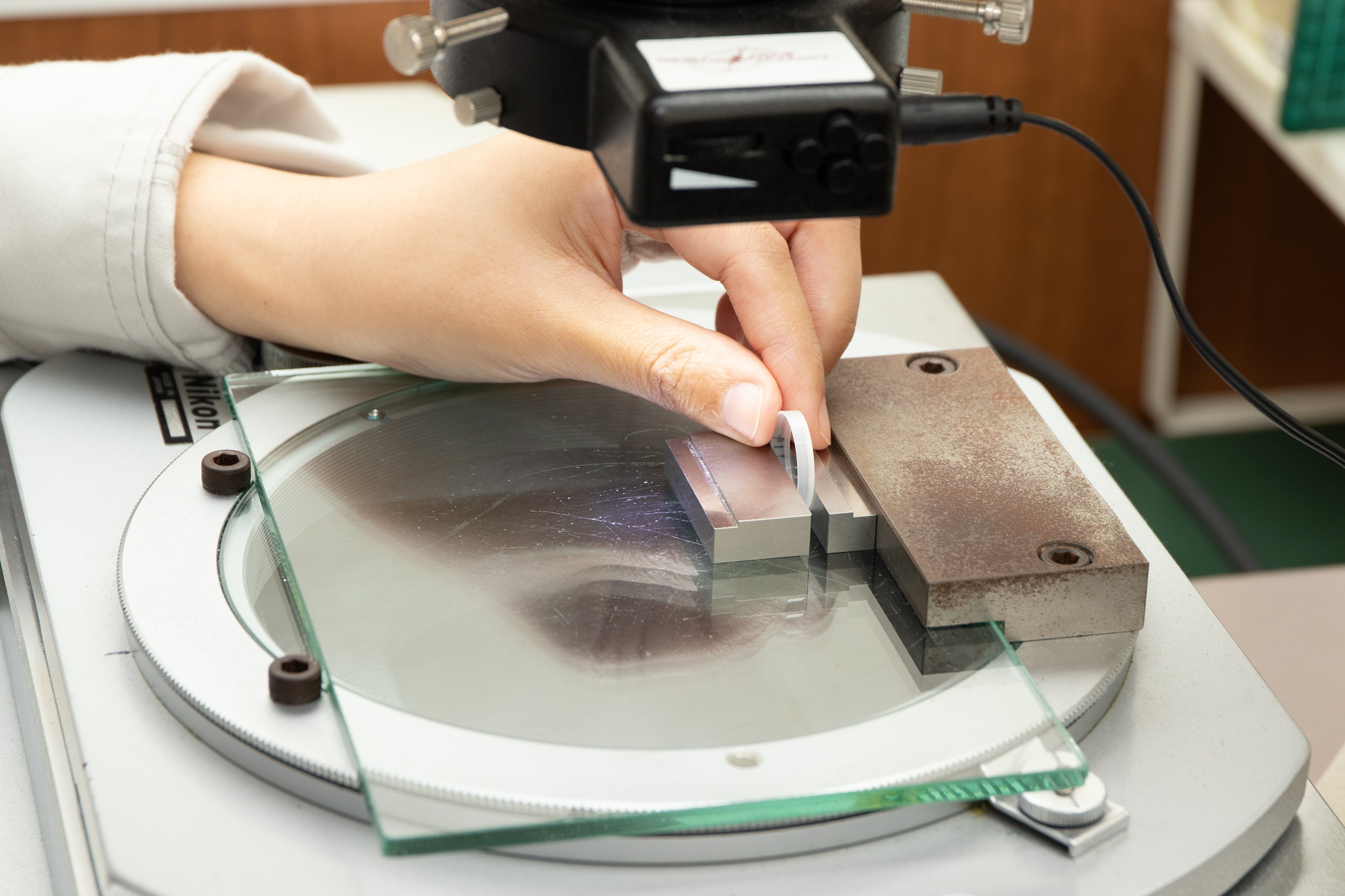

The quality assurance department, central to ESTOH's commitment to quality, has maintained a zero-complaint record for gasket production. The team developed a proprietary system that automatically feeds each product, one by one, from the mold into inspection, enabling full-scope visual checks for burrs and bubbles. Additionally, sampling inspections by molding and quality control staff, as well as visual inspections using stereo microscopes, help prevent defects from occurring on the line. Roughly 1% of each lot is also inspected manually under a magnifying microscope.

As part of dimensional accuracy management, a full inspection is conducted once per day on every injection molding machine using 3D measurement devices, tool microscopes, and automated measuring systems. Molds themselves are regularly inspected and maintained to ensure both long mold life and consistent dimensional accuracy.

By maintaining high technical standards across departments, ESTOH achieves stable, large-scale production with minimal variation, an essential source of its competitive advantage.

Nurturing young engineers to sustain manufacturing excellence

ESTOH operates across three sites: the Head Office Plant, the Hirano Plant (Hirano-ku, Osaka), and the Joto Plant (Joto-ku, Osaka). The Hirano Plant, which is considered a core production base, operates around 50 injection molding machines 24 hours a day and is home to many younger employees. Even mold inspections and maintenance are handled by workers in their twenties, who disassemble and service molds piece by piece.

To reduce size and extend mold life, ESTOH employs pinpoint gate designs, an advanced method that uses intricate flow paths to inject material from the product surface. This approach not only makes it easier for molded parts to detach after each shot but also requires highly complex mold shapes that are difficult to manage. ESTOH’s ability to entrust such delicate mold handling to young engineers is one of its key strengths.

At the Hirano Plant, approximately 50 injection molding machines operate 24 hours a day. Every aspect, from material supply to molded product ejection, is automated, including full-image inspection, allowing the plant to be run by a minimal number of operators working in three shifts. Prototyping of new orders is also underway at this site. Even while producing over 400 million pieces per month company-wide, the plant remains clean and efficient. Looking ahead, ESTOH is considering introducing digital technologies beyond image inspection, such as predictive maintenance, to further reduce operator workload. Advanced analytical instruments are also being actively adopted in the quality assurance department to ensure world-class quality standards.

These efforts also support recruitment. According to Atsushi Uchida, Head of the Mold Technology Department, even mid-career hires from other companies are “stunned by the level of precision here and find they need to relearn even the basics.” As a result, ESTOH has developed a comprehensive training system to support its employees.

Leveraging strengths in microfabrication

ESTOH’s integrated system — from micro mold design to molded product production and quality control — has its roots in the manufacture of electronic products like connectors, which the company has handled since its founding in 1991. As society and industry have evolved, with, for example, mobile phones giving way to smartphones, ESTOH’s product lineup has shifted accordingly. However, “the core technology of manufacturing highly precise plastic products hasn’t changed,” says Takamichi Ieshige, Executive Director of Production. ESTOH’s expertise in mass-producing small plastic parts with zero complaints has become a powerful asset in the advanced field of LiBs for EVs. Even as a member of the NOK Group, that core strength remains unchanged. “I hope we can apply ESTOH’s capabilities to other products as well,” Ieshige adds with optimism.

Continuing to adapt for further growth

The future of EV-use LiBs remains uncertain, and for ESTOH, the challenge ahead is to flexibly respond using its technological strengths. Currently, ESTOH excels in gaskets for cylindrical cells, but if prismatic types used in PCs or laminated types used in some vehicles become more widespread, the company’s current advantages may be harder to leverage. With research advancing on all-solid-state batteries as well, the competitive landscape could shift dramatically. For ESTOH to grow, adapting to these kinds of changes will be essential.

At the same time, it will be crucial to establish a second pillar beyond gaskets for EV LiBs. Understanding user needs and conducting research and development for new products will be key to opening up new fields — and this is where becoming part of the NOK Group is expected to pay off. Fields such as medical and biotech offer many potential opportunities for applying ESTOH’s technology. What shape ESTOH will take as it grows from here is an exciting prospect.

(Photo: Left)

Takumichi Ieshige

Executive Director of Production

Since joining ESTOH, Ieshige has worked primarily in plastic molding. He became Factory Manager of the Hirano Plant in 2011 and has overseen both production and production control departments as Executive Director since 2022. He is currently leading efforts within the NOK Group to standardize plastic molding technologies and promote smart factory initiatives where people and machines collaborate.

(Photo: Right)

Atsushi Uchida

Head of Mold Technology Department, ESTOH Co., Ltd.

Uchida joined ESTOH in 2020 to lead its Mold Technology Department. He draws on experience in mold design and fabrication from his previous role and is responsible for introducing mold automation systems. Today, he is focused on cross-functional collaboration in mold design and production across the NOK Group.

- Note:Data, positions and titles in this article are current as of February 2025.