Unlocking New Value for Users Via Data Utilization

Over its 84-year history, NOK has accumulated an extensive body of knowledge about materials, product functionality, structural design and production related to its core oil seal business. By digitizing, analyzing and leveraging this data, the company is pursuing initiatives that enhance its operational efficiency and swiftly responding to evolving user needs. A key element in this data utilization is artificial intelligence (AI). NOK collaborates with the data science division of its capital and technology partner, Germany's Freudenberg Group, to pursue various upgrades in efficiency.

Expanding applications of data science

At the heart of NOK's digital transformation is its data science team at the Shonan R&D Center (Fujisawa City, Kanagawa Prefecture). This team collaborates with experts in materials and production to drive digitization across different fields. According to Daisuke Mizukawa (Section Manager, Information Technology Development Section, System Development Department, Group R&D), data analysis initially focused on production planning, process information, and manufacturing data. Now, however, it encompasses all areas, including equipment monitoring, material research and electricity consumption management. Daily operational adjustments, which once relied on the intuition and expertise of skilled workers and R&D experiments, are now occurring at an accelerated pace, automatically and intelligently, via data analysis. Generative AI, a widely discussed technology, is also gradually being incorporated, with applications ranging from searching internal regulations to automatically generating reports on equipment failures.

NOK develops many of its digital technologies in-house. By integrating external expertise while aligning with onsite needs, Mizukawa notes, the company is building and deploying new system concepts.

AI-powered image analysis

"AI is highly compatible with image processing," Mizukawa explains. NOK is actively integrating image analysis into its production sites, expanding its applications. Many image inspection systems are already operational, performing automated visual checks to bolster product quality assurance.

One example of AI-driven innovation is a system that reads analog meters on production equipment using cameras and converts those readings into digital data. This eliminates errors and automates record-keeping. Since it was developed in-house, the system can quickly adapt to various meters — such as those measuring pressure, temperature and humidity — without requiring extensive modifications. Looking ahead, NOK envisions deploying drones equipped with cameras to autonomously collect equipment data, eliminating the need for human intervention.

Another development is a system that uses camera images to analyze worker movements and tasks. The system can break down work processes and identify inefficiencies by detecting skeletal movements. Productivity analysis typically required a dedicated observer to collect data manually. Automating this process with cameras makes precise task analysis possible without the ambiguity of human judgment. And by monitoring daily operations, the system can detect hazardous movements and issue alerts to help prevent injuries, such as those caused by poor posture.

Beyond these applications, NOK is researching ways to reduce manual labor through robotics. This includes developing systems to check for missed steps during equipment setup and maintenance using camera-based monitoring. Robots are also expected to be deployed to transport in-process materials and to assemble components in molding machines. In gasket production, for example, inserting metal rings into heated molds is a high-risk task that would be rendered much safer with robotic automation. Additionally, in mixing machinery, incomplete shaft cleaning can lead to product defects. By leveraging image-based inspection, NOK intends to implement stricter quality control compared to human checks.

Leveraging technology learned in Germany

NOK is exploring ways to apply the Freudenberg Group's data science expertise to its own operations. Daisuke Mizukawa spent two years on assignment at Freudenberg Technology Innovation (FTI), the Freudenberg Group's R&D arm, where he refined his data science skills.

FTI conducts R&D in three key areas utilizing data science. The first is data analytics, which involves AI-driven image analysis. The second is system ICT, which integrates IoT (Internet of Things) and other related technologies. The third is materials informatics (MI), which employs computational science for materials development.

In materials informatics, research is conducted across multiple scales—from the angstrom level (one ten-billionth of a meter) to the nano (one hundred millionth), micro (one millionth), and milli scales. By analyzing molecular structures at each of these levels and integrating the findings, researchers enhance materials development.

NOK's R&D division continues to strengthen its collaboration with FTI by sending engineers to exchange knowledge and expertise.

Please enlarge the screen to view

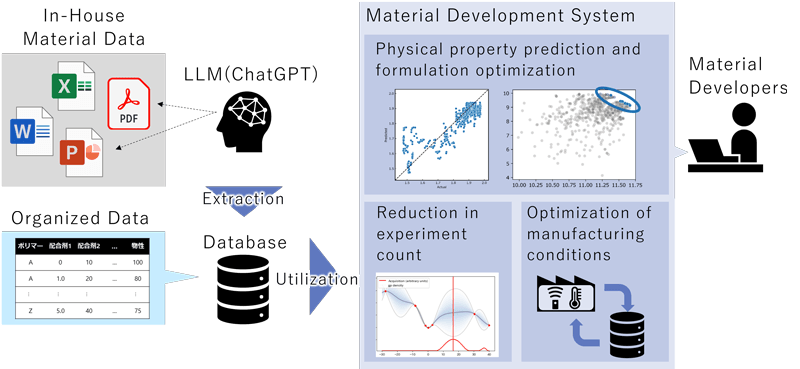

Applications in material development and labor optimization

NOK is advancing the use of AI in material-related applications. As indicated above, MI is a major focus, with efforts underway to integrate various datasets into large language models and build a structured database for analysis and utilization. "By reducing the need for physical experiments and prototyping, we can accelerate development," Mizukawa explains. "Additionally, we can identify factors, such as temperature and pressure conditions, that were not fully explored in past experiments, thereby improving data accuracy."

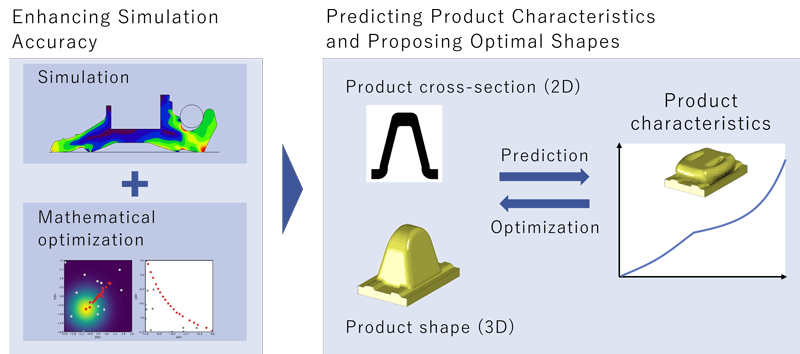

NOK is also working to enhance simulation accuracy through surrogate modeling, a method that predicts optimal product structures and shapes. This approach helps eliminate inefficiencies in development and enables more precise product proposals.

Please enlarge the screen to view

Another focus area is leveraging natural language processing to convert implicit knowledge into structured data, which can be then used for equipment maintenance and failure prediction.

However, NOK's use of data science extends far beyond simply reducing workloads and improving operational efficiency. "We aim to create an environment in which AI-driven innovation can thrive across all fields, from data-driven management and intelligent information technology to the adoption of AI agents and digital twins," says Mizukawa, outlining an ambitious vision for the future.

Daisuke Mizukawa

Section Manager, Information Technology Development Section, System Development Department, Group R&D, NOK Corporation

Daisuke Mizukawa specialized in mechanical engineering during his graduate studies. Since joining NOK in 2001, he has been involved in developing image inspection systems, product traceability systems, and new imaging-based devices. In 2022, he was assigned to Freudenberg Technology Innovation (FTI) in Germany to establish a technological collaboration framework in data science. He assumed his current role in October 2024 after returning to Japan, leading R&D efforts to create new value through data science and AI technologies.

- Note:Data, positions and titles in this article are current as of December 2024.