Leveraging Group Strengths to Develop FPC-Based Cell Separation Devices

NOK is set to celebrate its 100th anniversary in 2041. As part of its long-term initiatives, the company has identified wellness-related fields — including life sciences and healthcare — is priority areas for innovation. Within this focus, NOK is striving to commercialize cell separation technology using flexible printed circuits (FPC) — a product line that exemplifies the synergy created through the specialized expertise of its Group companies. FPC are the flagship products of Mektec, a NOK Group company engaged in the manufacture and sales of electronic products. Headquartered in Tokyo's Minato Ward, and known globally as a leading player in the FPC market, Mektec is now advancing research and development to harness the unique advantages FPC bring for cell separation devices.

Industry-academia collaboration aiming for practical use

FPC are products formed by laying down electrical circuits on a substrate made of a thin, flexible and insulating base film such as polyimide, and laminated with a conductive metal such as copper foil. Their greatest feature is extreme thinness and flexibility, which has boosted demand for them in components that undergo repeated bending, such as hinges in mobile phones and arms in hard disk drives. FPC are thin and lightweight — properties that have become highly valued in recent years, contributing to their widespread adoption in numerous electronic devices, including smartphones and wearable devices, and driving the miniaturization and slimming of technology.

The NOK Group is currently collaborating with assistant professor Kim Soo Hyeon, a leading researcher in biomedical microsystems in the University of Tokyo's Faculty of Engineering. Together, they are crafting a compact cell separation device using dielectrophoresis technology. Keisuke Ueda, from the NOK Group's Solution Development Section 1 in the R&D Mobility Product Development Department, expresses his enthusiasm: "Assistant professor Kim's research on biomedical microsystems is globally outstanding. We intend to combine it with the NOK Group's technology to create a product that stands unrivaled."

Advanced device for damage-free cell separation

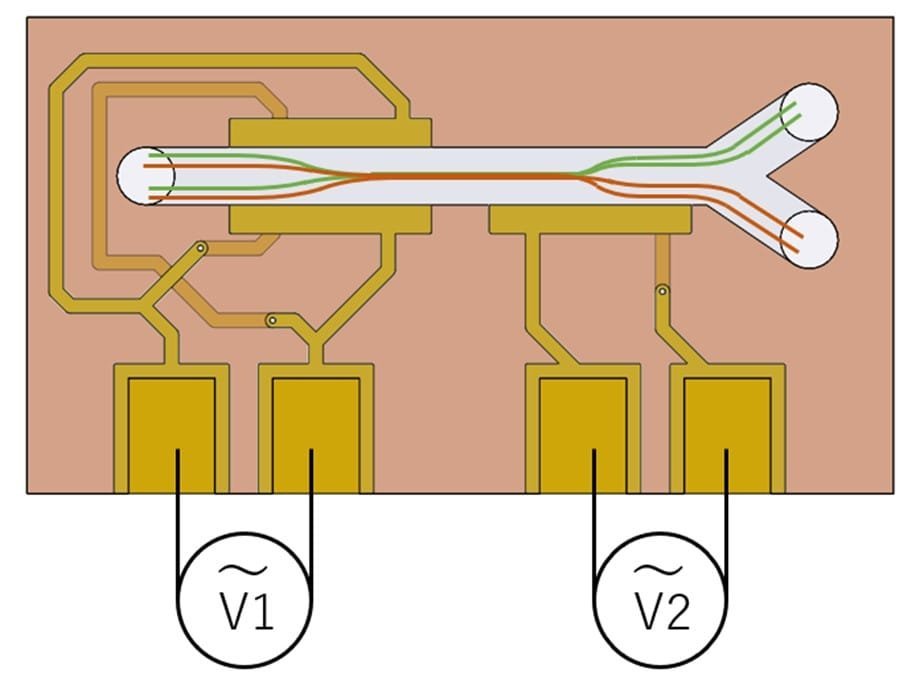

The cell separation device currently under development is approximately three centimeters by six centimeters in size. It features a channel in the middle that is measured in micrometers (millionths of a meter) in width, with four electrodes placed along the channel. The end of the channel splits into a Y-shape, dividing into two paths. Blood is passed through the channel, where an electric field (see note below) generated by the electrodes separates the cells needed for research or treatment — such as cancer cells — from unwanted cells.

- Note:Electric field: The region or space around an object that has a voltage applied to it.

Please enlarge the screen to view

For example, consider a scenario in which only cancer cells need to be extracted from a patient's blood. Two of the electrodes in the channel ensure that all cells flow through the center of the path. The remaining two electrodes gauge the differences in properties between normal cells and cancer cells, such as shape and surface area. Cancer cells are drawn toward the electrodes using an electric field by leveraging these differences. This process is controlled by adjusting the frequency of the electric field. Because this method separates cells based on differences in their electrical properties, it is not limited to cancer cells. It can even be applied to extract specific bacteria or to separate induced pluripotent stem cells (iPS cells) from other types of cells, broadening its potential uses.

Cell separation devices that use microchannels are typically made by attaching electrodes to a glass substrate. However, since FPC are constructed by laminating thin films with copper foil, they allow for the simultaneous creation of both the channels and electrodes. This makes them well-suited for mass production. One manufacturing challenge is ensuring liquid does not leak from the FPC channels. This requires sealing the channels with a rubber layer that can withstand high pressure. Since the device also handles biological samples, it is crucial to prevent adhesives from seeping into the channels. With NOK's extensive expertise in rubber and adhesives, developed through its flagship oil seals and O-rings, the company can employ safe, optimal structures and materials.

The global market for cell separation has been growing steadily in recent years. While methods that use markers or magnetic forces do exist, dielectrophoresis is the only technique capable of separating cells of the same size without causing damage. As a result, expectations for its practical application are high.

Overcoming challenges to achieve practical application

Despite their potential, there are challenges to the practical application of FPC-based cell separation devices. One challenge is that they are not suited for high-throughput processing. The width of the channel cannot exceed micrometer dimensions; a wider channel would weaken the force the electrodes exert. To address this, NOK is exploring a solution that increases the number of channels in the device.

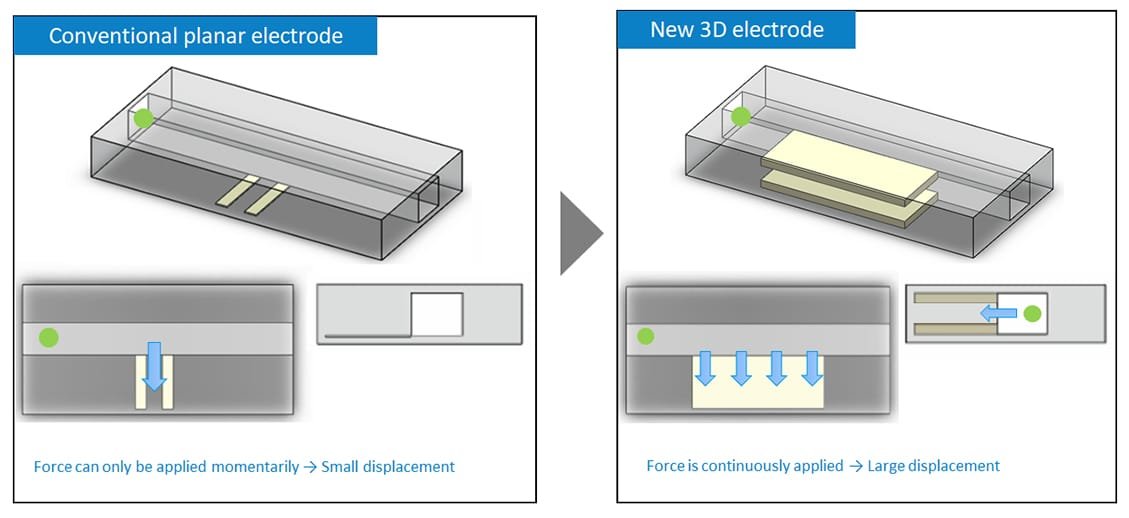

Another issue is that the precision of cell separation using this method is currently lower than that of other techniques. To tackle this, NOK is leveraging the multilayer structure of FPCs to arrange electrodes in a three-dimensional configuration, enhancing separation accuracy. This approach has already been patented.

Please enlarge the screen to view

"If we consider full commercialization as 100, we are at about 50," says Ueda. The team is conducting repeated experiments to complete a research-use prototype by 2025. Beyond that, for full-scale commercialization, NOK is exploring collaborations with companies that possess distribution channels and expertise, such as inspection equipment manufacturers.

Keisuke Ueda

Solution Development Section 1, NOK Group R&D Mobility Products Development Department, NOK Corporation

After specializing in organic materials engineering in graduate school, Keisuke Ueda joined NOK and worked in the new product development division, focusing on life science fields such as microfluidic PCR devices and nanopore devices. Since 2022, he has been involved in the research and development of the current cell separation device.

- Note:Data, positions, and titles in this article are current as of September 2024.