Expanding FPC Applications: Opportunities in Vehicle Electrification

Flexible printed circuits (FPC) are thin and flexible circuit boards that enable the miniaturization of electronic devices and improve component mounting capabilities. Mektec, based in Minato City, Tokyo, and led by President Taro Ito, is part of the NOK Group and plays a key role in its electronic products business. Mektec holds the third-largest global market share in FPC sales. Since it began operations in 1969, Mektec has pioneered the domestic FPC market, leading its growth and development.

World-class FPC for automotive batteries

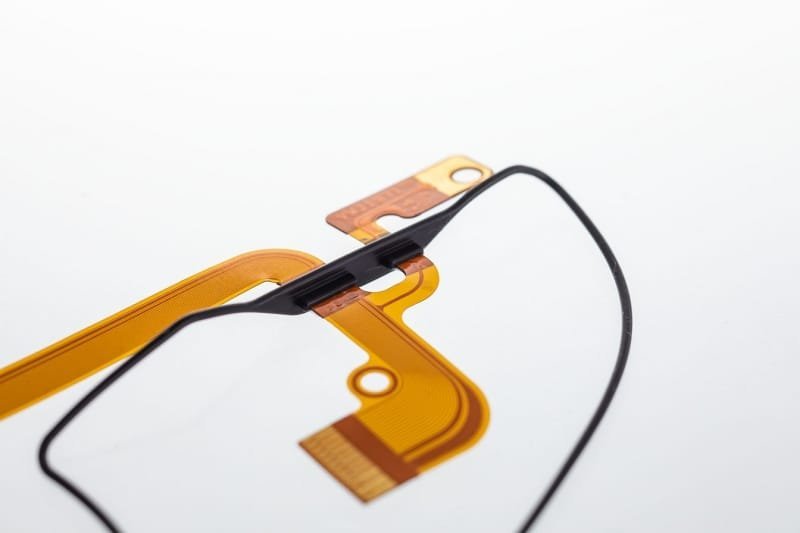

Flexible printed circuits (FPC) are thinner, lighter and more flexible than rigid circuit boards. These characteristics have made them a staple in products such as single-lens reflex cameras, hard disk drives and mobile phones, driving the growth of Mektec alongside advancements in electronic devices.

In FY2022, Mektec's product sales breakdown showed that mobile phones, including smartphones, accounted for 51%, while automotive applications accounted for 25%. To reduce reliance on the highly volatile mobile phone market, the company plans to lower the proportion of mobile-related sales while increasing the ratio of automotive-related sales, a sector with anticipated market expansion. By FY2025, the company aims for mobile and automotive-related sales to each account for 40% of its total revenue.

To expand its presence in the automotive FPC market, Mektec is leveraging its strengths: advanced technologies and product capabilities developed as an FPC pioneer, 14 global production sites enabling local supply to customers, and the collective strength of the NOK Group. It was among the first to commercialize FPC for battery voltage monitoring systems in electric vehicles (EVs). These FPC are now widely used by Chinese battery manufacturers as EV adoption accelerates, driving strong sales growth and helping Mektec achieve a world-class share in FPC for automotive batteries.

Mektec produces FPC for use in prismatic cells, laminated cells and cylindrical cells for automotive batteries, and the company can produce long versions exceeding two meters. In addition to developing FPC materials tailored to customer needs, Mektec offers integrated capabilities, including component assembly, connector mounting, and conformal coating processes. Junichiro Kita, manager of Sales Section 3, Sales Department 2 at Mektec's sales division, predicts that "FPC sales for automotive batteries will continue to increase in line with growing demand for EVs," and adds that Mektec is enhancing proposals to customers. The company plans to capture the expanding global demand for electric vehicles.

The advantages of using FPC in next-generation vehicles

The utilization of FPC in automotive components offers cost savings compared to using traditional cables that connect individual parts. For example, in a column switch, they reduced the number of parts used from 14 to 4. They also enable fine patterns and connector-less designs, contributing to component miniaturization. Integrating substrates, connectors and wiring can also significantly reduce the number of components, cutting out manufacturing steps and simplifying assembly. The ability to bend and route FPC in three dimensions also increases design flexibility.

One example is automotive lighting. Beyond the traditional purposes of illumination, for example, there is a growing trend to incorporate entertainment value. With their long length and wide-scale features, the FPC NOK produces are effective for ambient lighting that simulates a starry sky on a car's interior ceiling or for display functionalities in EV front grille spaces — made possible by the absence of engine cooling requirements.

Demand for FPC are also expected for heaters that target specific areas — such as defogging cameras and sensors in next-generation vehicles — thin radiant heaters that efficiently warm the driver and passenger seats, and wiper heaters to prevent washer fluid from freezing. These applications highlight significant business opportunities to leverage the technological capabilities of the NOK Group.

Additionally, advanced driver-assistance systems (ADAS) and autonomous driving technologies have spurred growth in high-performance sensors like LiDAR. Mektec's integrated gasket FPC, which prevent the entry of water and dust, has been adopted by overseas automotive manufacturers. This innovation also reduces production steps, enhances waterproofing for LiDAR devices, and improves maintenance convenience for customers.

This technology originated from solutions developed for mobile phones, and marks the first application of consumer-grade technology adapted for automotive use — a trend the company aims to expand. Rintaro Katayose, deputy general manager of Sales Department 2, expressed confidence, stating: "Our FPC are built on decades of expertise, and have the power to create new applications and shape the future of mobility."

The company has in-house capabilities for material evaluation, testing and simulation design for newly developed products, supported by robust facilities and expertise. By combining its established technological strengths with innovative products and solutions, the company seeks to achieve sustainable growth.

(Top photo)

Junichiro Kita

Section Manager, Sales Section 3, Sales Department 2, Sales Division, Mektec Corporation

Junichiro Kita has worked as a sales representative for major Japanese consumer electronics and automotive manufacturers in Osaka, Thailand, Tokyo and Singapore. From 2019, including during the COVID-19 pandemic, he spent three years as a project manager at the Zhuhai factory in China, where he handled new projects for automotive applications. He now oversees the promotion and management of sales for overseas automotive batteries and other automotive applications in the sales division.

(Bottom photo)

Rintaro Katayose

Assistant Department Manager, Sales Department 2, Sales Division, Mektec Corporation

After joining Mektec, Rintaro Katayose was engaged in FPC manufacturing and implementation technologies until 2017, working on product and process development, prototyping, and mass-production launches. During this time, he was seconded to Thailand as a manager in the technical department. Since 2017, he has specialized in FPC application engineering used in automotive batteries, focusing on expanding sales. He now supports the sales activities of branch offices and sales companies and manages sales and marketing operations.

- Note:Data, positions and titles in this article are current as of February 2024.