NOK to Exhibit at Automotive Engineering Exposition 2025 in Yokohama

Debuting New Materials and Components Designed for the Evolving Needs of Electric Vehicles

NOK Corporation (Headquarters: Shibadaimon, Minato-ku, Tokyo; Representative Director, Group Chief Executive Officer: Masao Tsuru; hereinafter referred to as "NOK") will exhibit at the Automotive Engineering Exposition 2025 at PACIFICO Yokohama (Nishi-ku, Yokohama, Kanagawa Prefecture) from Wednesday, May 21 to Friday, May 23. At the exhibition, NOK will unveil five newly developed products for electric vehicles for the first time, highlighting the NOK Group’s latest efforts to meet the evolving needs of mobility.

The display will feature a range of technologies that enhance safety and comfort in electric vehicles, including a new rubber material with enhanced tracking resistance for high-voltage environments, high-speed-compatible seals, and thermal management materials.

With its philosophy of “Essential Core Manufacturing — the manufacture of pivotal products that shape society,” NOK is helping to create a safer and more comfortable future for mobility through innovative, technology-driven products.

Newly developed product / First public exhibit

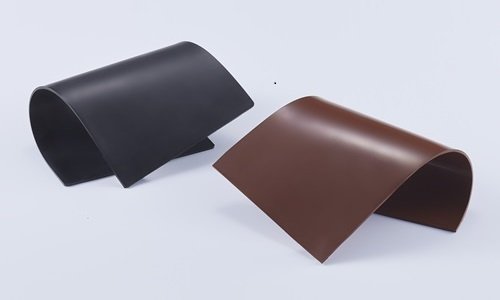

Thanks to a proprietary compound formulation developed in-house, this rubber material suppresses tracking phenomena in high-voltage environments. It meets a Comparative Tracking Index (CTI)* of 600, the highest level defined by JIS standards. Molding the material into parts with added sealing functionality contributes to space-saving around inverters and motors while reducing the number of components required. In addition, the base rubber can be customized for specific applications, with options that offer water or oil resistance.

*The CTI (Comparative Tracking Index) indicates the durability of an insulating material against tracking. A higher value means greater resistance to tracking.

New product / First public exhibit

This newly developed oil seal features NOK’s proprietary “VF Thread” design, engineered to support high-speed rotation in both forward and reverse directions. It maintains sealing performance at high surface speeds of up to 50 m/s in both directions — approximately 2.5 times the capacity of conventional bidirectional oil seals. The VF Thread incorporates V-shaped protrusions on the lip, enabling efficient oil recovery. By optimizing the shape of these protrusions, the seal retains high durability and delivers excellent sealing performance even after wear. This product is designed for use in high-speed, bi-directionally rotating components such as motors in electric vehicles and robotics.

New product / First public exhibit

This newly developed seal ring combines a textured surface with deep grooves that supply oil to the sliding area and an asymmetrical (crescent-shaped) design that enhances conformity to the housing. Together, these features achieve both low torque and low leakage. Compared to conventional products, torque has been reduced by approximately 70% and leakage by about half. This seal ring is ideal for use in areas where hydraulic pressure retention is critical, such as automatic transmissions.

New product / First public exhibit

This gasket is designed for aluminum housings — including those used in electric vehicle units — and provides enhanced resistance to saltwater corrosion. The addition of a specialized aluminum anti-corrosion coating fills in the surface roughness of aluminum housings, significantly improving corrosion resistance. Two types of gaskets are available: a rubber gasket and a rubber-coated metal gasket made by bonding rubber to a steel plate.

New product / First public exhibit

This seal for multi-channel switching valves combines rubber and low friction material and is designed with a unique shape that achieves both high sealing performance and low torque. It enables smooth switching between flow paths while minimizing energy loss. Reducing the number of surrounding components allows for more efficient use of limited thermal energy. Two types will be showcased: a rotor type and a disc type.

・Thermally Conductive Material Series

NOK’s thermally conductive material series is designed to support effective thermal management of devices. The clay-type material, which is soft and moldable, conforms to complex, uneven surfaces, enabling efficient heat dissipation. NOK also offers customized shapes tailored to specific applications, including composite products that combine clay with rubber.

This insulating resin material combines excellent heat dissipation with high heat resistance. It can be molded with high precision and offers a lightweight alternative to conventional metal components, contributing to overall vehicle weight reduction. Designed for continuous use in high-temperature environments (up to 220°C), it is suitable for components that demand high thermal conductivity and thermal durability, such as busbars and connectors in motors, batteries, and inverters.

<NOK Booth at the Automotive Engineering Exposition 2025 (Yokohama)>

・Organizer: Society of Automotive Engineers of Japan, Inc.

・Dates: Wednesday, May 21 - Friday, May 23, 2025

May 21 (Wed) & May 22 (Thu): 10:00 AM - 6:00 PM

May 23 (Fri): 9:00 AM - 4:00 PM

・Venue: PACIFICO Yokohama, Exhibition Hall North

1-1-1 Minato Mirai, Nishi-ku, Yokohama, Kanagawa

NOK Booth Number: N05

・ Access:

Approx. 5-minute walk from Minatomirai Station (Minatomirai Line)

Approx. 12-minute walk from Sakuragicho Station

(JR Yokohama Line / Yokohama Municipal Subway Blue Line)

・Event Website: https://aee.expo-info.jsae.or.jp/en/yokohama/

For inquiries related to this press release

Corporate Communications, Corporate Affairs Group, CEO Office, NOK Corporation

TEL: +81-3-5405-6372

Mail: mb_nok_corporate_affairsjp.nokgrp.com